How to connect PE fittings

PE fitting connection

PE pipe fittings connection is PE pipe, pp pipe connection, according to the interface form and heating can be divided into two ways.

1 PE pipe connection form

General requirements for installation

Electric fusion connection

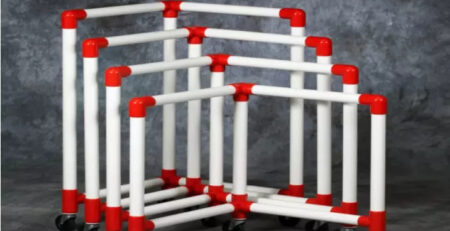

PE fitting connection form

The connection of PE pipe fitting and pp pipe fitting can be divided into:

1. Electric welding connection: electric welding socket connection and electric welding saddle connection

2, hot melt connection: hot melt socket connection, hot melt saddle connection, hot melt butt connection

General requirements for installation

1. Before the PE pipeline is connected, the pipes, fittings and auxiliary equipment shall be checked according to the design requirements, and the appearance inspection shall be conducted on the construction site to meet the requirements before use. Main inspection items include pressure rating, surface quality, fit quality, material consistency, etc.

2. Special heating tools shall be adopted according to different interface forms, and PE pipes and fittings shall not be heated with open flame.

3. For PE pipes connected by welding, it is advisable to use pipes and fittings of the same grade material. For those with similar performance, they must be tested and qualified before proceeding.

4. PE pipes and fittings shall be connected after they have been placed on the construction site for a certain period of time, so as to keep the temperature of pipes and fittings consistent

5. When connecting in cold weather (below 5 ° c) and windy environment, protective measures or adjustment of connecting process should be taken.

6, PE pipe connection pipe end should be clean, each time the end of the pipe should be temporarily blocked to prevent debris into the pipe.

7. The PE pipeline shall be inspected for appearance after connection, and the unqualified shall rework immediately.

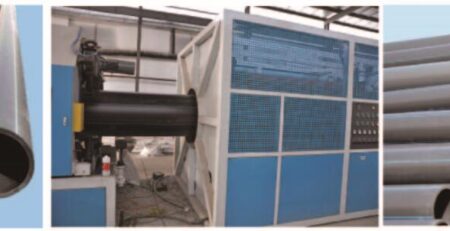

Fused connection

First, the electric melting tube is set on the tube, and then the electric melting tube is electrified with special welding machine according to the specified parameters (time, voltage, etc.), so that the inner surface of the electric melting tube embedded with electric heating wire and the outer surface of the tube insertion end are melted. After cooling, the tube and the tube are fused together. Its characteristic is the connection is convenient and quick, the joint quality is good, outside factor interference is small, but the price of electric melting pipe fittings is a few times to dozens of times of common pipe fittings, (diameter is smaller the difference is bigger), suit for the connection of large diameter pipe generally.

1. Procedure (process) of welding socket and socket connection

Check – in cutting – clean joint parts — — — — — tube piece into the pipe – correction electric welding — — — — — – — — — – cooling

(1) pipe cutting: the connecting end of the pipe shall be cut vertically to ensure sufficient hot melt zone. Commonly used cutting tools are rotary cutter, saw bow, plastic pipe scissors; Cutting is not allowed to produce high temperature, so as not to cause high temperature deformation.

(2) clean the joint and mark the insertion depth line: remove the oxide layer on the surface of the pipe with fine sandpaper and scraper, wipe the dirt on the connection surface of the pipe and pipe fitting with clean cotton cloth, and mark the insertion depth line.

(3) PE package into the pipe: the electric melting package into the pipe to the specified depth, and connect the welding machine with the pipe fitting.

(4) correction: adjust the position of the pipe and fittings so that the pipe and fittings are on the same axis to prevent the joint from being unsolidity and poor air tightness caused by eccentricity.

(5) power-on welding: the time and voltage of power-on heating shall be in accordance with the provisions of the electric welding machine and the electric melting pipe fitting manufacturer, so as to ensure that the best welding joint can be obtained under the optimal supply voltage and heating time.

(6) cooling: the PE pipe joint can only reach its maximum compressive strength after being cooled to the normal temperature. Other external forces during the cooling period will make the pipe and fittings unable to maintain the same axis, thus affecting the welding quality. Therefore, it is not allowed to move the connected part or apply external forces at the joint during the cooling period.