4 steps to distinguish the quality of PVC pipes and fittings

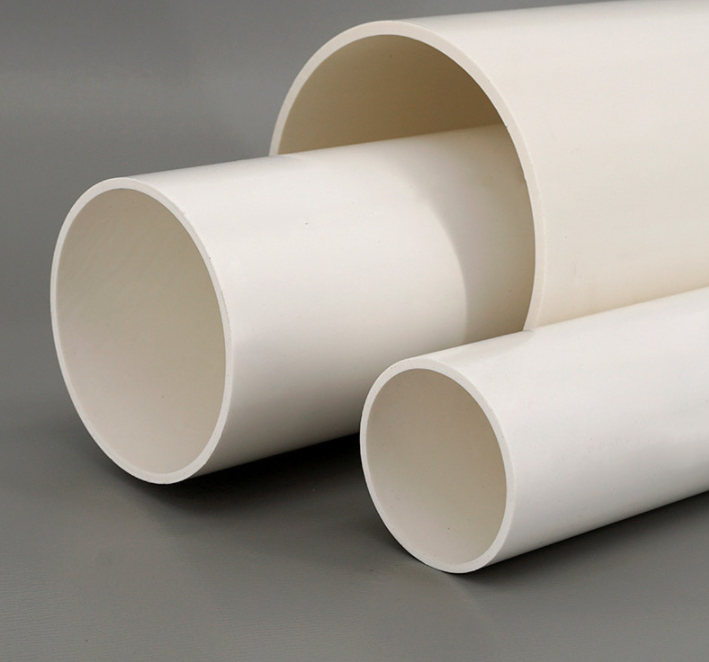

1. Judging from the appearance

a. From the color point of view, standard high-quality PVC-U pipes and fittings are light beige, with good surface gloss and oiliness, which are high-quality products. The inner wall is also very smooth. The PVC pipe fittings are well designed to realize the inner The surface connection is smooth and smooth, and the PVC water supply pipe and drainage are very smooth.

b. If the color of PVC pipes and fittings is too pale, it means that the calcium powder added to the product may be excessive, which is a substandard product.

c. If the PVC pipes and pipe fittings are black and yellow, and there are many spots, it means that the manufacturer may have added too many miscellaneous materials and recycled materials to the product.

2. Judging from the weight

a. Compare the weight of two pipes with the same diameter and wall thickness. The weight of the calcium powder is too much, the material is impure, and it cannot meet the requirements.

b. PVC pipes and pipe fittings with heavy hand feel have a lot of calcium powder added. According to national standards, PVC pipes and pipe fittings for different purposes are subject to corresponding standards. There are certain restrictions on adding calcium powder, which is reflected in the proportion of finished products. Some manufacturers desperately add calcium powder in order to reduce costs, which affects other performance indicators.

c. Some pipes are evacuated, and the wall thickness at both ends meets the requirements, but the middle wall thickness is thinner, which does not meet the requirements for use. At the same time, the cost is reduced through the method of evacuating.

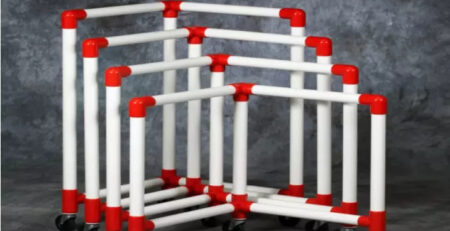

3. Judging from the hardness

a. Test the quality of PVC pipes and fittings by stepping on them. If possible, you can step on the edges of the PVC pipes and fittings with your feet to see if they can be easily broken. As long as the hardness and toughness of any good PVC pipe are very strong, even if it is rolled by a car, it will only be flat and not broken.

b. Inferior PVC pipes and fittings are mixed with excessive calcium powder during production, and they are easily broken when subjected to heavy pressure. In order to save costs and increase profits, some manufacturers add excessive amounts of calcium powder to the production of pipes. Such pipes are cheap, but their hardness is much lower, fragile, and unqualified.

4. Judging from the inspection report

a. The product test report is an intuitive presentation of product quality. Regular manufacturers will conduct regular product tests. You can directly ask the manufacturer for product test reports to check the authenticity.

1. Test report: The test report of the pipe and the test report of its health indicators should be obtained. It is best to look at the original.

2. Technical indicators;

3. Vicat softening temperature ≥ 80 ° C;

4. Longitudinal retraction rate ≤5%;

5. There is no change in the impregnation surface;

6. drop weight impact test (0 ° C) TIR ≤ 5c / o;

7. Hydraulic test in 20 degree environment, the ring stress is 36MPa/38Mpa, no crack after 1 hour, no leakage.

b. Ignite it with fire to see if it has a pungent smell and whether it is self-extinguishing from the fire. If it has a pungent smell, it means it is not environmentally friendly and harmful to the human body. Whether it is self-extinguishing from the fire is to judge whether it is flame retardant. It is also a very important indicator.

The PVC pipes and fittings produced by Shijiazhuang Xingyin Import and Export Trade Co., Ltd. are of very good quality, using the latest and greatest virgin materials