What is a pe water supply pipe?

PE water supply pipe is a pipe made of special polyethylene as raw material and extruded by a plastic extruder at one time. It has good weldability, environmental strain resistance, and rapid stress cracking resistance. It can be used safely for more than 50 years under rated temperature and pressure. Except for a few strong oxidants, it can withstand various chemical media. PE water supply pipe has good toughness, high impact resistance, and will not break the pipe due to external gravity. The strength of the hot melt or electric melt interface is higher than that of the pipe body, and the joint will not be broken due to soil movement or live load. The pipeline is light in quality, simple in welding, convenient in construction, and greatly reduces the project cost. The small diameter PE water supply pipe can be coiled, which reduces the number of interfaces and is convenient to connect. Mainly used in urban and rural tap water supply pipelines; gas pipelines (natural gas, liquefied gas, man-made gas, etc.); coal mine ventilation pipelines, slurry pipelines; centralized heating jackets; seawater and corrosive media pipelines; petroleum and chemical pipelines; sewage Pipe, cable sheath; water conservancy and farmland irrigation, etc.

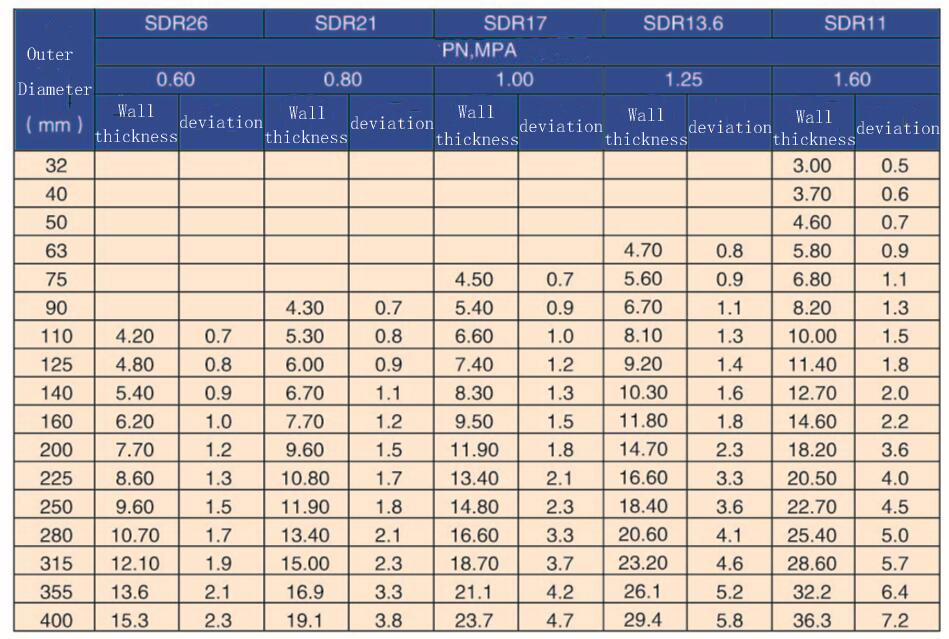

Product specifications

Features of pe water supply pipe:

Corrosion resistance

Polyethylene is a non-inert material, except for a small number of strong oxidants, it can withstand a variety of chemicals, and is not easy to breed bacteria. It is well known that the reason why steel pipes and cast iron pipes are replaced by plastic pipes is not only because plastic pipes have lower water consumption, lower life energy consumption, lightweight, small water flow resistance, simple and rapid installation, low cost, long life, and heat preservation function. It is also better than steel pipes and cast iron pipes because of its corrosion resistance and microbial resistance.

Flexibility

Polyethylene has unique flexibility and excellent scratch resistance. The flexibility of the polyethylene piping system has huge technical and economic value. The flexibility of polyethylene is an important property, which greatly improves the value of the material for pipeline engineering. The good flexibility allows the polyethylene pipe to be coiled and supplied in a longer length, avoiding a large number of joints and pipe fittings.

Low-temperature resistance

Polyethylene has very outstanding low-temperature resistance. The low-temperature embrittlement point of pe water supply pipe is -70℃, which is better than other pipes. Infield construction in winter, polyvinyl chloride (PVC-U) pipes are prone to brittle cracks. An experience summarized in the pilot project of laying polyvinyl chloride (PVC-U) buried water supply pipes in the Beijing area is that the temperature is not suitable for operations below zero. The laying of polyvinyl chloride (PVC-U) pipe was constructed.

Fracture toughness

Polyethylene has good fracture toughness with rapid crack growth. In the event of rapid crack growth and destruction, the crack can rapidly expand from several hundred meters to ten kilometers at a speed of 100-45m/s, causing damage to long-distance pipelines, large-scale leakage accidents, and subsequent combustion explosions (gas transmission) or floods ( Water delivery) accident.