What is the difference between PVC pipe fitting and PPR water supply pipe fitting?

Shijiazhuang xingyin import and export trade Co., Ltd. is pvc pipe fitting Manufacturer, pvc pipe fitting supplier in china.

we are also a ppr pipe fitting Manufacturer,ppr pipe fitting supplier in china.

We are a professional manufacturer of various plastic pipe fittings factory in china.

Let me introduce you:

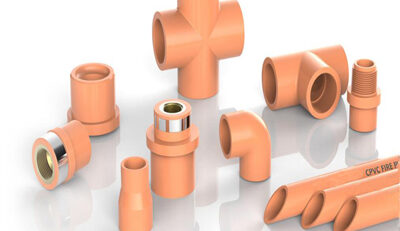

Performance characteristics of PVC pipe fitting products:

1. Light weight, easy to handle: PVC pipe and fitting is very light, easy to handle, convenient for construction, and labor saving.

2. Excellent chemical resistance: PVC pipe and fitting has friendly acid, alkali and corrosion resistance, which is suitable for chemical industry.

3. Low fluid resistance: PVC pipe fitting has smooth wall and low fluid resistance, and its roughness coefficient is only 0.009, which is lower than other pipes. Under the same flow rate, the small pipe diameter can be reduced.

4. High mechanical strength: PVC pipe fitting has good water pressure strength, external pressure strength, impact strength, etc., which is suitable for piping engineering under various conditions.

5. Good electrical insulation; PVC pipe fitting has rich and superior electrical insulation performance, which is suitable for wire and cable pipes and wiring pipes on buildings.

6. No impact on water quality: PVC pipe, confirmed by dissolution test, does not affect water quality. It is a good pipe for water supply pipeline at present

7. Simple construction; PVC pipe and fitting joint construction is fast and convenient. Therefore, the construction cost is low, and PVC pipe is suitable for use: water engineering, electrical engineering, construction engineering, sewage engineering, telecommunication engineering, drilling engineering, brine engineering, natural gas engineering, chemical plant, paper engineering, brewing and fermentation plant, electroplating plant, agricultural park, mining, aquaculture, highway engineering, golf course engineering, fishing plastic raft

As a new type of pipe, PP-R pipe fitting has the following characteristics:

1. Energy saving PP-R pipe fitting production energy consumption is only 20% of steel pipe

2. The use of corrosion-resistant, non scaling, sanitary and non-toxic PP-R pipes and fittings can eliminate the “secondary pollution” caused by scaling and corrosion on the inner wall of galvanized steel pipes. Because PP-R group is simple in composition and its basic components are carbon and hydrogen, it conforms to food hygiene regulations. Non toxic, more suitable for drinking water transportation.

3. Heat resistant, pressure resistant and long-life PP-R tube has a long-term working temperature of 95 ℃, short-term working temperature of 120 ℃, and a long-term continuous service life of more than 50 years under 70 ℃ and 1.2 MPa working pressure.

4. The density of light, high-strength and fluid resistant PP-R pipe and fitting is only 1 / 8 of that of metal pipe, and the compressive test strength is as high as 5MPa, with good toughness and impact resistance. Because the inner wall is smooth, not rusty, not scaling, and the fluid resistance is small.

PPR tube product features:

1. Non toxic and healthy. The raw materials of PP-R are only carbon and hydrogen. There are no harmful and toxic elements. They are reliable and can be used not only in hot and cold water pipes, but also in pure drinking water systems. 2. Heat preservation and energy saving. The thermal conductivity of PP-R pipe is 0.21w/mk, only 1 / 200 of that of steel pipe.

3. Better heat resistance. The Vica softening point of PP-R pipe is 131.5 ℃, and the high temperature operation temperature can reach 95 ℃, which can meet the requirements of hot water system in building drainage code.

4. Long service life. Under the working temperature of 70 ℃ and the working pressure of 1, the service life of P P-R tube can be more than 50 years. OmpA; at room temperature (20 ° C), the service life can be more than 100 years. Easy to install and secure connection. PP-R has good weldability. The pipe and the pipe part 5 can be connected by hot melting and electric melting. It is easy to install and the connector is firm. The strength of the connecting part is greater than that of the pipe itself.

6. Material recovery. PP-R waste is used in pipe production after cleaning and crushing. The recycled materials shall not exceed 10% of the total amount, which will not affect the product quality.