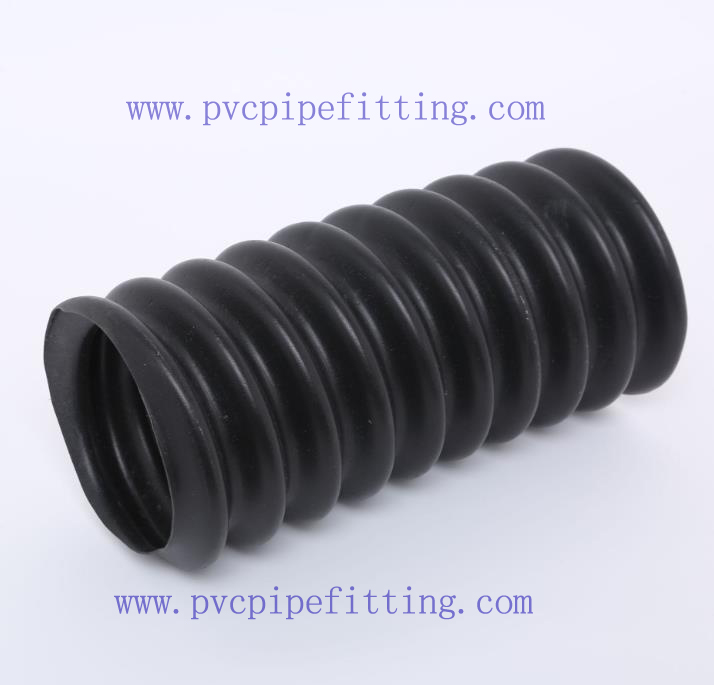

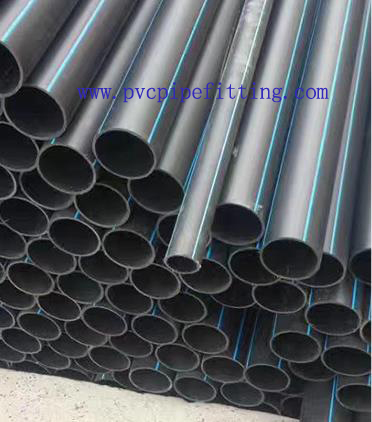

Pe cable (optical cable) protection pipe

PE cable (optical cable) protection pipe is a new type of casing material popularized and used in power engineering. With the rapid development of power cable buried laying projects, higher requirements are put forward for cable (optical cable) protection pipes. The cable (optical cable) protection pipes are made of polyethylene PE and high-quality steel pipes that have undergone sandblasting, shot blasting, plastic dipping Manufactured by coating, heating, and curing process. It is the most commonly used electrical insulating tube for protecting wires and cables. It is widely used because of its good insulation properties, high chemical stability, no rust, no aging, and adaptability to harsh environments.

Features of pe cable (optical cable) protection pipe

1. Corrosion resistance, long service life, and can be used in humid saline-alkali areas.

2. It is flame-retardant and heat-resistant. It can be used for a long time at a high temperature of 130 degrees without deformation and will not burn in fire.

3. High strength and high rigidity. It is used for direct burying under the carriageway without adding a concrete protective layer, which can speed up the progress of cable construction.

4. The pipe is flexible and can resist the damage caused by external pressure and foundation settlement.

5. It has a good anti-interference performance of external signals.

6. The inner wall is smooth and does not scratch the cable. The design adopts the socket connection mode, which is convenient for installation and connection. The rubber sealing ring seal at the joint not only adapts to thermal expansion and contraction but also prevents mud and sand from entering.

pe cable (optical cable) protection pipe product performance

1. High strength and high rigidity. It is used for direct burying under the carriageway without adding a concrete protective layer, which can speed up the progress of cable engineering construction.

2. The pipe is flexible and can resist the damage caused by external pressure and foundation settlement.

3. Corrosion resistance, long service life, and can be used in wet saline-alkali areas.

4. Flame-retardant and heat-resistant, it can be used for a long time at a high temperature of 130 degrees without deformation, and will not burn in fire.

5. The inner wall is smooth and does not scratch the cable. The design adopts the socket connection mode, which is convenient for installation and connection. The rubber sealing ring seal at the joint not only adapts to thermal expansion and contraction but also prevents mud and sand from entering.

Scope of application

It is suitable for telecommunications, power engineering, transportation, urban construction, and other fields.